Rotary UV Engraver

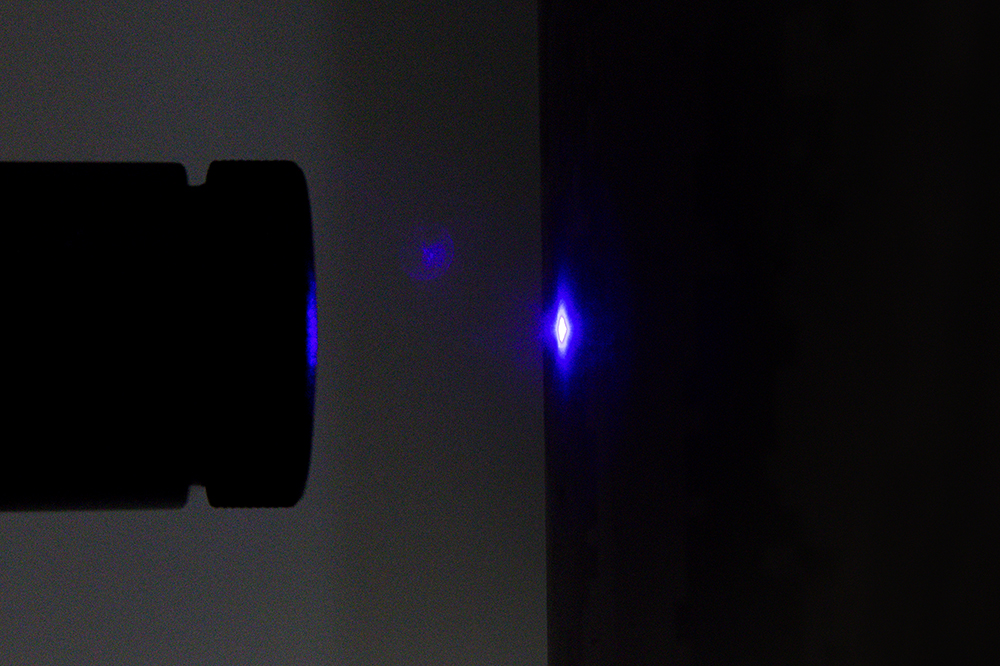

Use UV laser (wavelength 405nm) to accurately expose the photosensitive emulsion on the screen to achieve the purpose of screen making. Avoid film, ink and other media required in traditional screen making methods. It can improve the design accuracy on the screen, and greatly reduce the cost of use and maintenance.

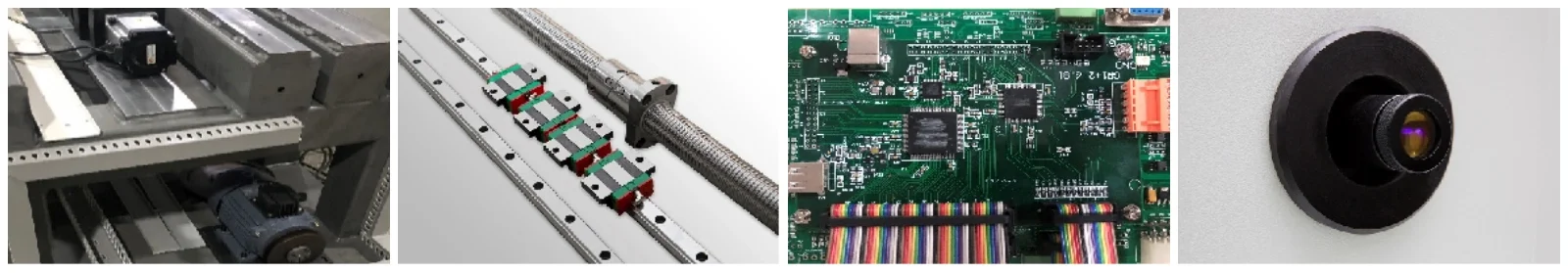

1. Mechanical structure

The main frame structure is welded by 100mm square tube, and the finishing of the whole machine is tempered to ensure the structural precision is constant.

2. Transmission component

Screw rods and guide rails are all selected from Taiwan or Germany brands. It fundamentally guarantees the stability and accuracy of the transmission.

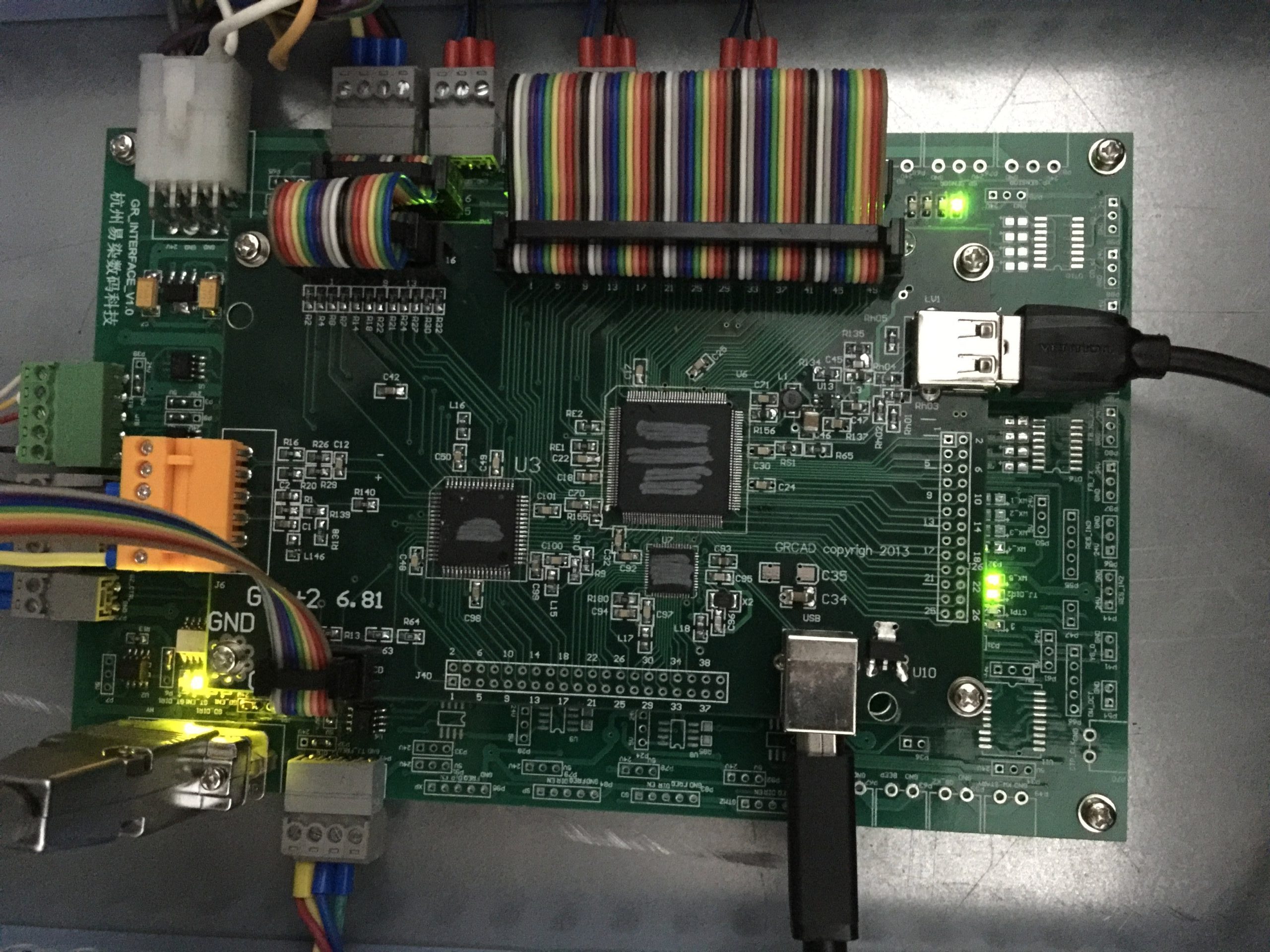

3. Control System

It adopts mature and reliable control system and is specially optimized according to our equipment.

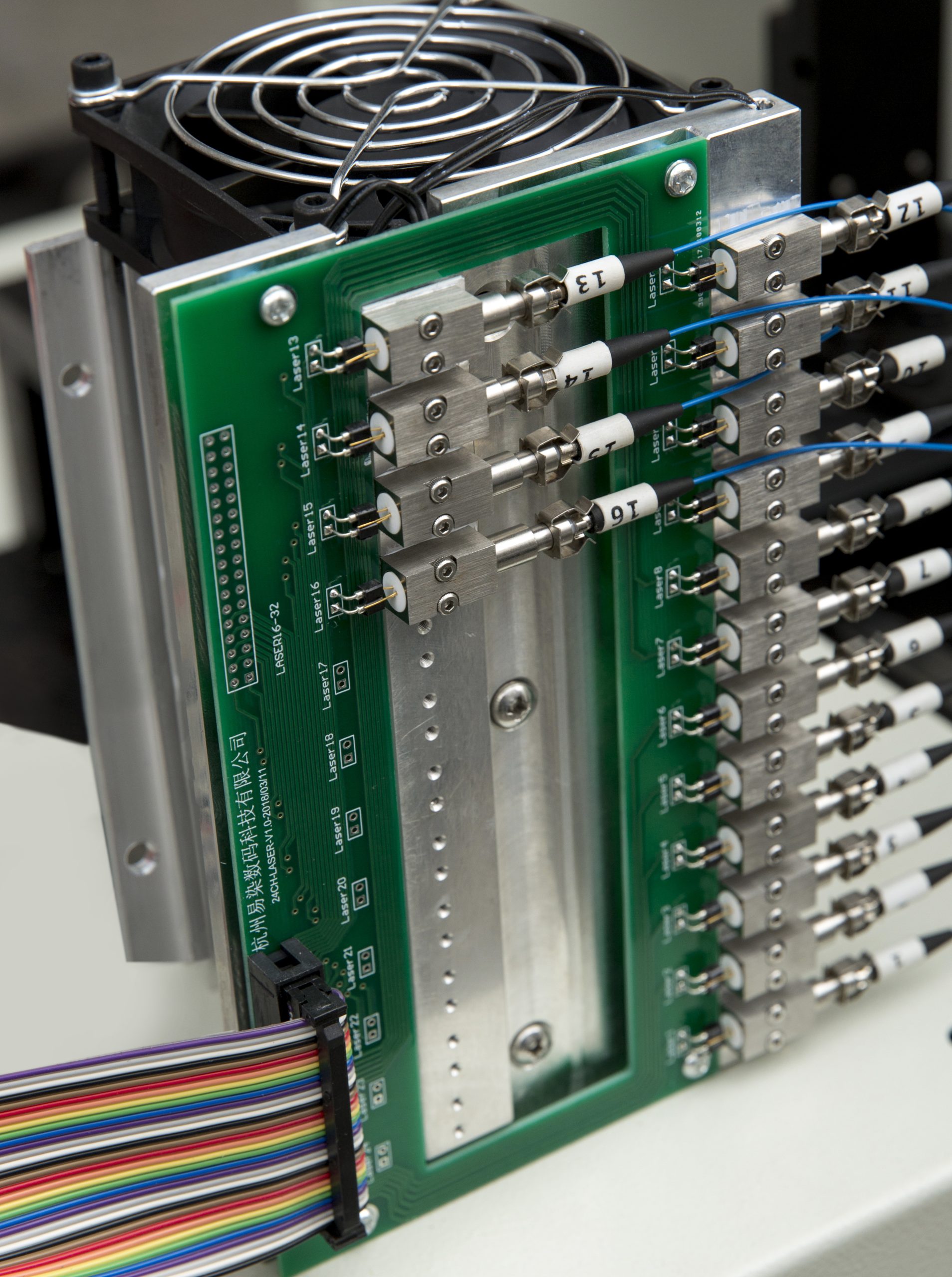

4. Laser system

The Laser generator is our customized product, and its service life and strength are higher than other existing Laser generator; the core lens uses a high-permeability large-caliber lens to ensure accuracy and transmittance. Achieve plate making accuracy of 1440dpi.

Reasons for choosing Jindian UV Engraving

Design: Comprehensive analysis of the advantages and disadvantages of major screen-making companies, preferably the frame structure, transmission components, optical components, software design, etc.

Produce: The professional plotter machine machinery, software and electrical personnel who have been engaged in the industry for more than 10 years ensure the stable operation of the product quality.

Upgrade: Close to customers, regularly collect and summarize customer requirements and requirements, continue to invest, and further improve product performance. At present, there are obvious advantages in equipment upgrade, precision improvement and speed improvement.

Team: 12 years of professional screen making service team 7 * 24 hours telephone service; regional office quick on-site service.

Effectiveness: Make full use of high-power laser generators and custom lenses to ensure the premise of plate making accuracy, to achieve adjustable network time, higher than the industry average network time.

Cost: Reasonable cost control, reducing the cost of customer use under the premise of ensuring the quality of equipment.

Screen making development history

![]() FRIST

FRIST

Hand work:All hand-drawn drafts are not accurate and inefficient.

![]() SENOND

SENOND

Film:From manual plate making to the era of computer screen making. It is difficult to overcome the round screen printing.

![]() THIRD

THIRD

Media printing:Although the accuracy of waxjet and inkjet is lower than that of film, it solves the problem of printing on the screen. However, the structure is complicated and the maintenance cost is high.

![]() FOURTH

FOURTH

UV Engraving: low cost, high precision and good stability.However, the photosensitivity is worse than the media.

![]() FUTURE

FUTURE

………………….

JinDian UV Engraving contrast inkjet machine advantage

Cost: Jindian UV Engraving zero consumables, maintenance costs are much lower than the inkjet machine.

Precision: The laser precision is higher than the ink drop precision, and the golden light blue terminal has a high light intensity. As long as the reasonable meshing process is combined, fine geometric patterns and halfton can replace the inkjet machine.

Effectiveness: Ready to use, no preheating required. The equipment failure rate is much lower than that of the inkjet. The screen is fast and easy to rinse.

Core: The intensity of the UV laser is greater than other UV laser in the market, ensuring the fastness of the photosensitive glue, thereby ensuring the stability of the net making effect. The electronic draft is seamlessly docked, and the electronic draft of the inkjet can be used directly without modification.

Jindian UV Engraver combines laser optics principles and digital technology, and uses a stable UV laser system to accurately focus and direct exposure screen making on the nickel screen pre-coated with photosensitive emulsion; accurately restore the design on the nickel screen, saving The operation process and cost of inkjet, wax , and film are eliminated to meet customers’ demand for high-quality and low-cost production of screen plates.

1. High precision: The highest precision of blue light screen can reach 1440dpi, and it can print negative lines with a width of 0.1mm. Makes high-precision moire, thin lines and other patterns to be perfectly reproduced.

2. Good stability: Imported screw, grating, guide rail and other precision transmission components are used to ensure long-term stability of the plate making effect.

3. Low cost: Because it relies on the selective exposure of laser signs, there is no need to use consumables such as wax, ink or film, so that the plate making is really zero cost during use.

4. Wide range of meshes: custom-made high-precision optical lens, perfect use of light source focusing accuracy, to achieve perfect mesh-making effect from 40 mesh to 195 mesh.

5. Nickel mesh automatic inflation: the equipment comes with an air pump, and the air pressure inside the mesh is detected in real time. Adjust the amount of inflation according to the detection value, and keep the air pressure standard in the network at all times.

6. Focus detection: The equipment is equipped with a Japanese Panasonic brand laser rangefinder to position the lens to realize real-time detection and ensure that the focus position error is within 0.02 mm.

7. Nickel mesh roundness detection and starting point detection: When the laser is turned on, the blue light machine scans the center of the nickel mesh with the largest deviation. If the deviation is within the allowable range, the starting point in the circumferential direction of the pattern is detected and adjusted, and the pattern is made to ensure the registration of the printing. problem.

| Model | JD2200 | JD3500 | |

| Printing resolution(DPI) | 600/720/1080 | ||

| Number of UV laser(piece) | 16/24/32 | ||

| Registering precision (μm) | 20 | ||

| Thinnest effective negative line width(mm) | 0.1 | ||

| Effective printing length (mm) | 500~2200 | 500~3500 | |

| Optional circumference (mm) | 640(Basic)、530、819、914、1018(Optiona) | ||

| Printing speed(min/㎡) | 8~10 | ||

| Image format | *.tiff, *.bmp | ||

| Power | AC220V, 2KW | ||

| Desktops | LENOVO DESKTOPS | E2-7110 | |

| OS | WIN7/WIN10 | ||

| CO-ROM | PROVIDE | ||

| External dimensions(L×W×H)mm | 3920×910×1400 | 5920×910×1400 | |

| Weight(kg) | 1000 | 1200 | |