Hydraulic oil-Water Stripping Machine

It is used to clean the photosensitive glue which is solidified on the surface of the nickel screen, so that the nickel screen can be reused.

Main features

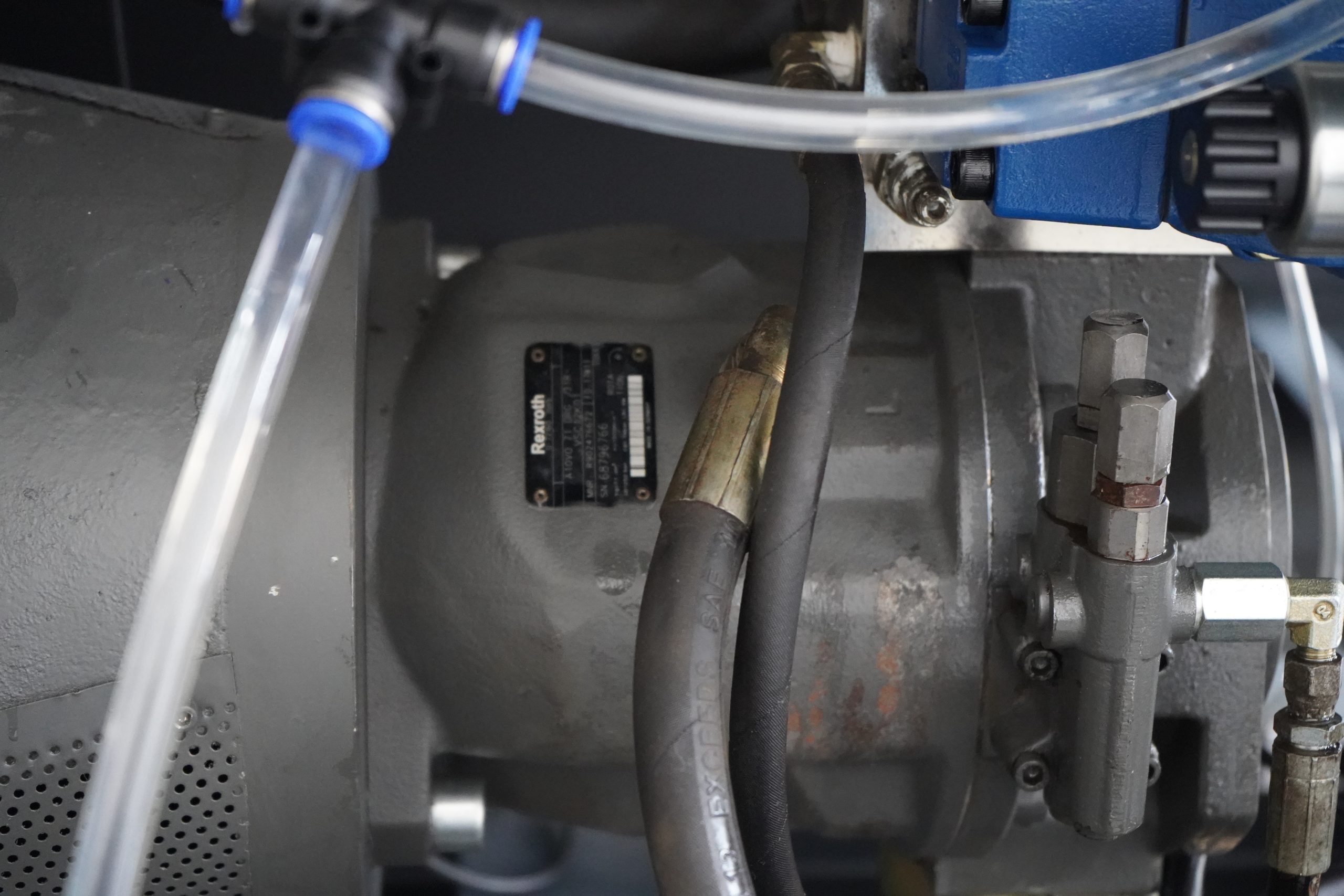

1.High stability: The system adopts the most advanced turbocharger system in Germany. The output of the system is stable and the pressure is stable, and the penetration rate of 40-155 mesh nickel net can reach 99.9%.

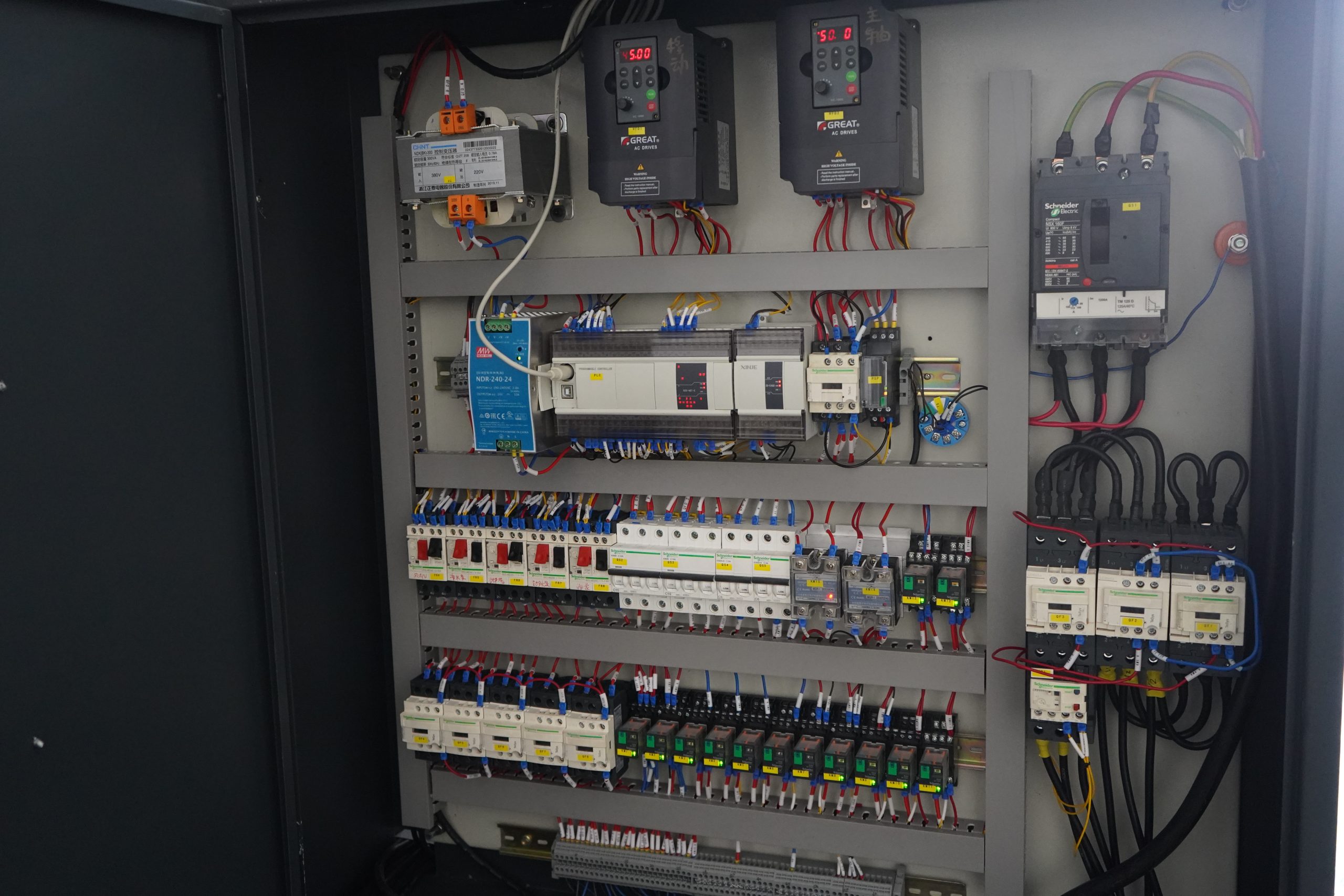

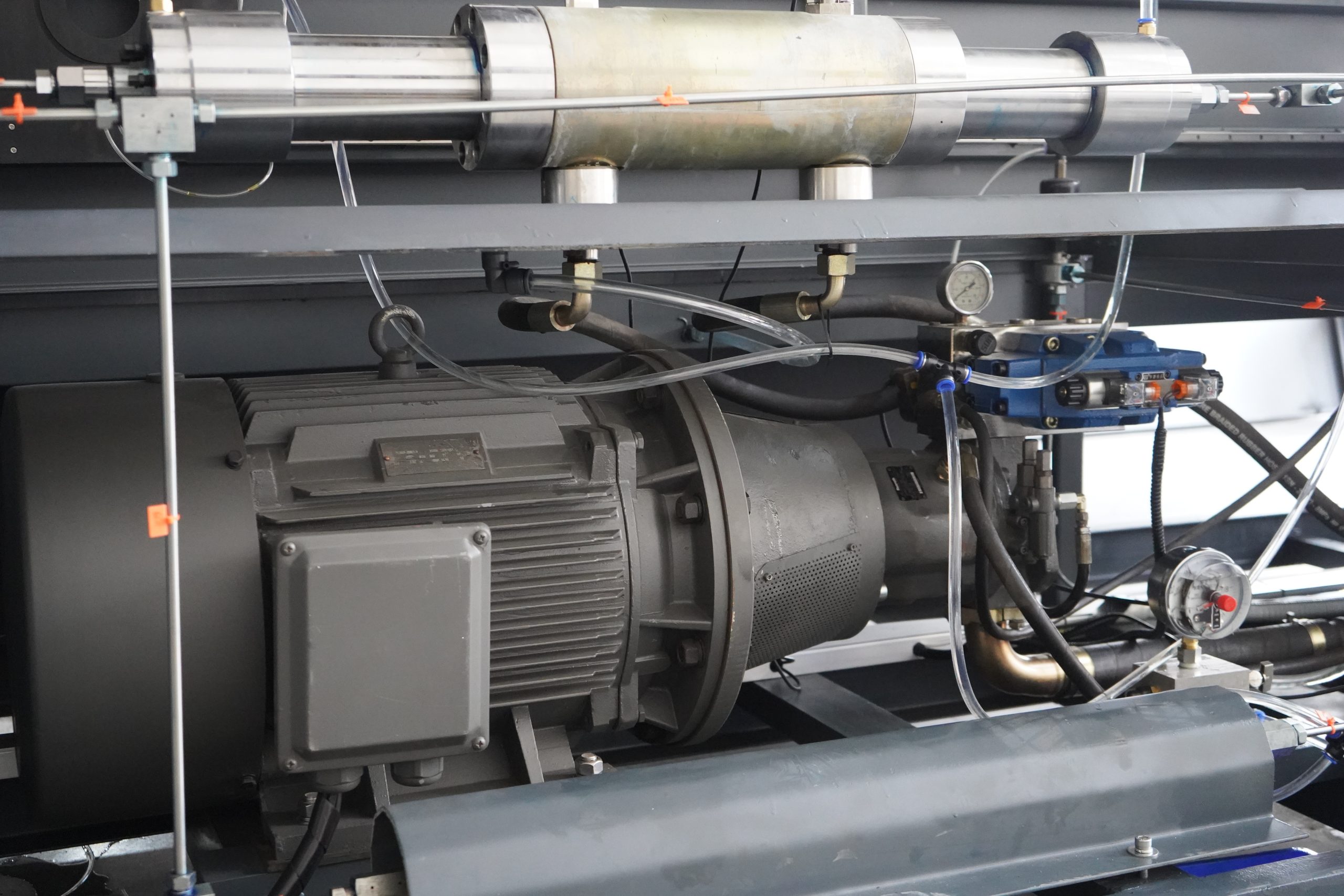

2.Low cost: the main motor uses German SIEMENS, the main electrical components of Schneider, energy saving to 50%.

3.High efficiency: the installation of the imported accumulator and high pressure pipeline to ensure the continuous operation of the equipment. Free and stew head, save labor, one key operation.

High safety: the valve blocks, pipeline blocks and high pressure pipes connected by equipment are imported from the United States, and integrated with mature technology, which occupy less space and ensure safety.

Clean and environmental: pure water cleaning, do not use any chemical agents, non-toxic and non – toxic to the human body and the environment will not cause any harm.

The effect is remarkable: every nickel screen can be used many times, and the cost of recycling and utilization is about US$4 per time, which has reduced a lot of round nickel screen purchase cost for the manufacturers, and has notable energy saving, environmental protection and synergistic effect.

| Model | JD2200H | JD3200H | |

| Working pressure(mpa) | 200~350 | ||

| Number of nozzles(piece) | 3+2 | ||

| Ultra-high pressure water flow (l/min) | 3 | ||

| Maximum cleaning width (mm) | 2200 | 3200 | |

| Optional circumference (mm) | 640(Basic)、819、914、1018(Optiona) | ||

| Cleaning speed(min/㎡) | 3.5 | ||

| Power | AC380V, 37KW | ||

| System control | Way to control | PLC and operation screen | |

| Motion mechanism | Triple-phase asynchronous motor | ||

| High pressure system | Manual control | ||

| External dimensions(L×W×H)mm | 4500×1600×1500 | 5500×1600×1500 | |

| Weight(kg) | 3000 | 3500 | |