Textile Industry Digital Printer 32

Digital printing is a modern fabric printing method that combines mechanical, electrical, and computer technology. It uses on-demand inkjet printing, which is eco-friendly and energy-efficient. Unlike traditional printing, it allows unlimited colors and design sizes, eliminates the need for screens and color paste, and offers higher precision. It is especially suitable for small to medium orders with multi-color, high-detail, personalized, and large-size designs that require fast delivery.

Product Introduction

Digital printing technology is a new fabric printing method integrating machinery, electricity and computer electronic information technology. It is characterized by inkjet on demand, environmental protection and energy saving. Digital printing technology enables printed fabrics to break the limits of the number of colors and design sizes traditionally produced. Compared with traditional printing methods, it saves the process of design, screen production and color slurry preparation, and can also achieve higher precision for printed fabrics. Especially small and medium batches of multi-color, high-precision,personalized, large-size design and fast delivery printed cloth orders are suitable for the application characteristics of digital printing machines.

Product features

Industrial print head:

Ricoh or Kyocera’s industrial grade print heads better meet the needs of industrial production High-precision:

Using magnetic levitation linear motor, printing accuracy is higher. Advanced Ink System:

The application of negative pressure ink circuit control system and ink degassing system greatly improves the stability of inkjet. Automatic cleaning:

Equipped with an automatic cleaning system for the guide belt to ensure continuous production and improve production efficiency. Automatic structure:

Active rewinding/unwinding structure to ensure stable stretch and shrinkage of the fabric.

| Model | JD1800D32 | JD2700D32 | JD3200D32 | |

| Printhead | Brand Model | Kyocera KJ4B / Ricoh MH5320 | ||

| Arrangement | 4×8 | |||

| Quantity/Color | 32 Print heads/8 Colors | |||

| Print resolution | 508~1200DPI | |||

| Maximum print width | 1800MM | 2700MM | 3200MM | |

| Print speed(8 Colors) | 1PASS | 600M²/H | 840M²/H | 930M²/H |

| 2PASS | 470M²/H | 660M²/H | 730M²/H | |

| Ink | Type | Reactive ink/Disperse ink/Pigment ink/Acid ink | ||

| Color | C,M,Y,K +4 Other Colors | |||

| Color Mode | 4,6,8 Color Model | |||

| Applicable fabrics | Cotton, linen, silk, wool, chemical fiber, blended. Woven or knitted fabrics of various new fibers | |||

| Software | RIP | Neostampa/Wasatch/Texprint | ||

| Image Type | Tiff/Jepg/Eps/Pdf | |||

| Machine Features | Fabric feeding | Automatic constant tension feeding | ||

| Printing Hight | 2~30MM | |||

| Fabric drying | Hot air drying oven | |||

| Ink System | Industrial-grade negative pressure degassing ink supply | |||

| Head cleaning | Auto head cleaning & auto scraping device | |||

| Belt cleaning | Intellingent spray/Multiple levels Drying | |||

| Work environment | Power supply | 380VAC±10%,50/60HZ 3P | ||

| Power | 20KW For Printer,20~80KW For Dryer | |||

| Air Supply | 0.6~0.8MPA, 0.15 m³/h | |||

| Water Supply | 0.6MPA,0.9 m³/h | |||

| Tem&Hum | 25-30 ℃, 60-80% | |||

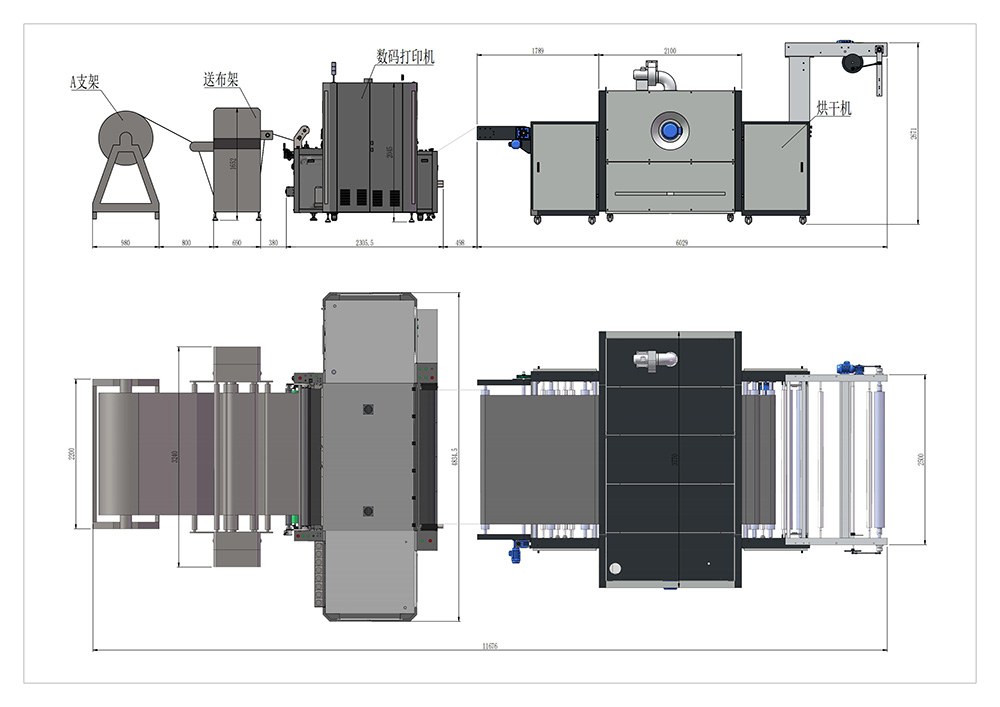

| Dimension | Size | 4860×2340×2300MM | 5860×2340×2300MM | 6360×2340×2300MM |

| Weight | 4700KG | 5500KG | 8700KG | |